The Rotary Piston Vacuum Pump is designed to perform in the most demanding environments. With its robust construction and high reliability, it is the ideal solution for applications requiring a strong, long-lasting vacuum pump with extended service intervals. This pump delivers excellent performance even in challenging industrial conditions.

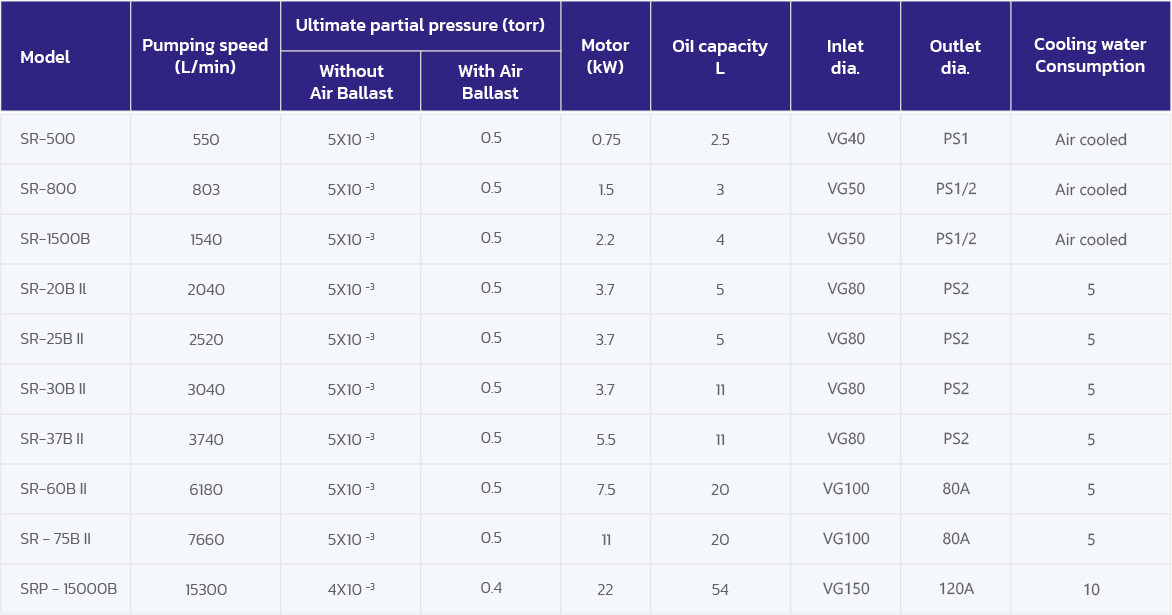

This single-stage design pump offers a wide pumping speed range from 30 m³/hr to 900 m³/hr, an ultimate partial pressure of up to 5 x 10⁻³ torr. Its durable construction makes it ideal for continuous operation in harsh industrial applications e.g. Furnace and Metallurgy, High vacuum coating, Autoclave,. The Rotary Piston OTO series is available upon request for specialized requirements in Chemical or Pharmaceutical applications. With its extended service intervals, this pump minimizes downtime and ensures efficiency in a variety of industries.

Product Category: Vacuum Pump

With over 5,000 successful installations across diverse industrial applications in India, our rotary piston vacuum pump stands validated by widespread industry acceptance and a strong performance track record.

Engineered with a rugged construction that significantly reduces wear and tear, this design minimizes maintenance needs while ensuring consistent, long-term reliability even in demanding operating conditions.

Designed for heavy-duty, round-the-clock usage, the system performs reliably in applications requiring sustained high vacuum levels without performance drop or operational fatigue.

Optimized for simplicity, the equipment requires fewer service interventions, resulting in reduced maintenance budgets, quicker installation, and lower overall cost of ownership.

Manufactured in Japan, a benchmark for engineering precision and quality, the product reflects superior craftsmanship, long service life, and dependable performance over years of operation.

Backed by a strong and well-distributed service infrastructure across India, we ensure prompt response times, quick issue resolution, and minimal downtime. Our trained service engineers, readily available spares, and regionally located service team enable reliable after-sales support throughout the equipment lifecycle, regardless of your plant location.

The pumping speed ranges from 30 m³/hr to 900 m³/hr & Ultimate vacuum of 0.005 torr making it suitable for various industrial processes.

The pump’s robust design, made from high-grade cast iron, allows it to perform reliably in tough operating conditions. Piston Pumps has fewer parts, runs at lower RPM, large pumps are water cooled design this helps to reduce the impact of harsh environment and operating conditions. E.g. higher inlet gas temp, higher ambient temperature, higher vapour load.

Industries such as pharmaceuticals, electrical, and vacuum furnace manufacturing benefit from the pump’s high vacuum capability and stable pumping speed.

Yes, the simple design with fewer parts of the piston pump ensures easy maintenance and does not require highly skilled manpower, reducing overall maintenance costs.

The OTO series offers superior vapor handling capacity and efficiency with a single motor mechanism and low oil consumption, making it a cost-effective solution for the process industry. The oil provides corrosion protection to contact components, reducing the adverse effects of corrosive vapours.