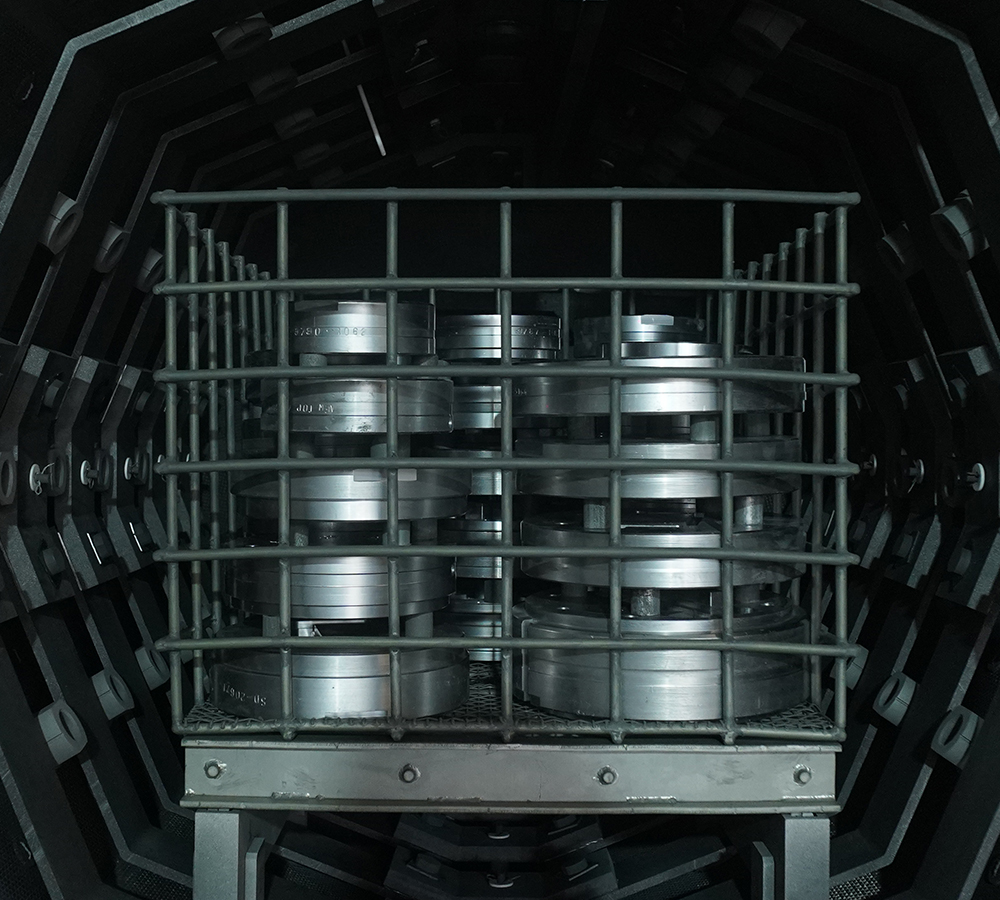

Product Category: Vacuum Furnace

Built to comply with global standards and equipped with all essential features, our furnaces offer precise temperature control to ensure uniform quality across every production batch.

Suitable for Hardening, Annealing, Tempering, Brazing, and Sintering, covering a broad spectrum of industrial heat-treatment applications.

Engineered with robust construction and zero compromise on quality, our furnaces are built to last for at least 15 years.

Designed for safe operation under high temperatures and pressures, backed by code compliance, good engineering practices, high-quality components, and stringent quality checks.

Our advanced designs ensure lower energy consumption, resulting in consistently reduced operating costs.

While not the cheapest upfront, our efficient design, faster process cycles, high reliability, minimal maintenance, and superior uptime translate into significantly lower lifetime ownership costs.

Easy-maintenance design layouts, easy to operate HMI screens, and simplified troubleshooting ensure smooth and efficient operation.

Deep knowledge of processes, metallurgy, and business needs; allows us to guide customers toward the best heat-treatment solutions.

A vacuum furnace is a specialized heating chamber that operates under vacuum conditions, allowing for precise control over temperature and atmosphere during various thermal processes.

A vacuum environment minimizes oxidation and contamination, ensuring high-quality results in processes like heat treatment, brazing, and sintering.

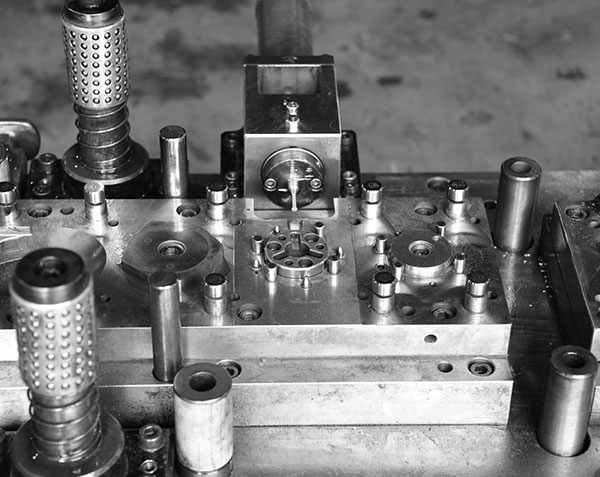

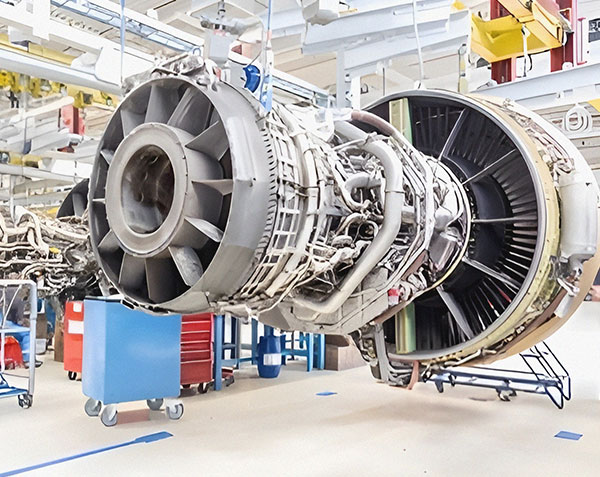

Our furnaces can handle a wide range of materials, including metals, alloys, and advanced materials like titanium alloys, superalloys and zirconium-based alloys used in industries like aerospace, automotive, and medical applications. They also support processes like vacuum sintering and vacuum brazing, enabling clean, high-purity treatment of reactive or exotic metals that would otherwise oxidize or degrade under conventional heating.

The choice of configuration depends on factors such as the type of material, the required process, and the desired production volume. Our team can help assess your needs and recommend the best option.

Vacuum furnaces offer a clean, oxygen-free environment that prevents oxidation and ensures superior surface quality. They provide precise, uniform temperature control for consistent, high-quality heat-treatment results, along with higher energy efficiency and faster processing

Yes, Vacuum Furnaces are equipped with safety features to ensure safe operation, including safety temperature controller, pressure monitoring with safety electrical & mechanical valves and emergency shutdown systems.

Rapidly cools the heated metal by injecting high-pressure inert gas (like nitrogen or argon), locking in a hard, wear-resistant microstructure such as martensite. Because the process happens under vacuum, oxidation and decarburization are prevented, resulting in a clean surface and more uniform hardness from surface to core. Also, the controlled, uniform cooling reduces distortion and residual stress — giving better dimensional stability and reliability in final parts.

Yes, we offer intensive training programs for operators to ensure they understand how to safely and efficiently use the vacuum furnaces. Auto and manual operations, maintenance like preventive and breakdown.

We provide comprehensive support services, including installation, maintenance, troubleshooting, and access to replacement parts.

For more information, you can visit our website, contact our sales team, or request a product demonstration to see the capabilities of our vacuum furnaces in action.