Product Category: Vacuum Accessories & Oil

Tekman has supplied a wide range of vacuum pumps and engineered vacuum pumping systems for diverse industrial applications. This extensive experience enables Tekman to accurately design, manufacture, and select the right accessories and system configurations to suit specific application requirements.

All accessories are designed to operate consistently in harsh industrial environments, ensuring stable performance, reduced downtime, and long service life.

Select accessories, such as our Lubricant Cleaning & Conditioning System (LCCS), incorporate patented separator technology that delivers superior separation efficiency and consistent system performance.

Optimized accessory design helps reduce oil contamination, component wear, and unplanned breakdowns—resulting in lower maintenance costs and extended pump life.

Our technical experts assist customers in selecting the right accessories based on pump type, operating conditions, process requirements, and performance objectives

Manufactured using proven components and robust construction practices to ensure durability, reliability, and dependable long-term operation.

Strong service network and readily available spares across India ensure quick support, minimal downtime, and peace of mind for customers.

Focused on delivering long-term operational value through improved pump efficiency, reduced consumable usage, and enhanced system reliability.

More than a supplier, Tekman works as a long-term partner committed to performance, reliability, and total lifecycle value for every customer.

Tekman offers fully integrated vacuum pumping systems with suitable accessories and built-in automation. The systems can be supplied with features such as auto drain and auto gas ballast, which help reduce manual intervention and ensure consistent, reliable operation.

We supply a complete range of industrial vacuum pump accessories, including LCCS (Lubricant Cleaning & Conditioning Systems), vacuum sealed suction filters, vacuum bellows, oil and dust separators, liquid cyclonic separators, inlet liquid traps, special hoses and fittings, valves, gauges, and other critical components for industrial vacuum systems.

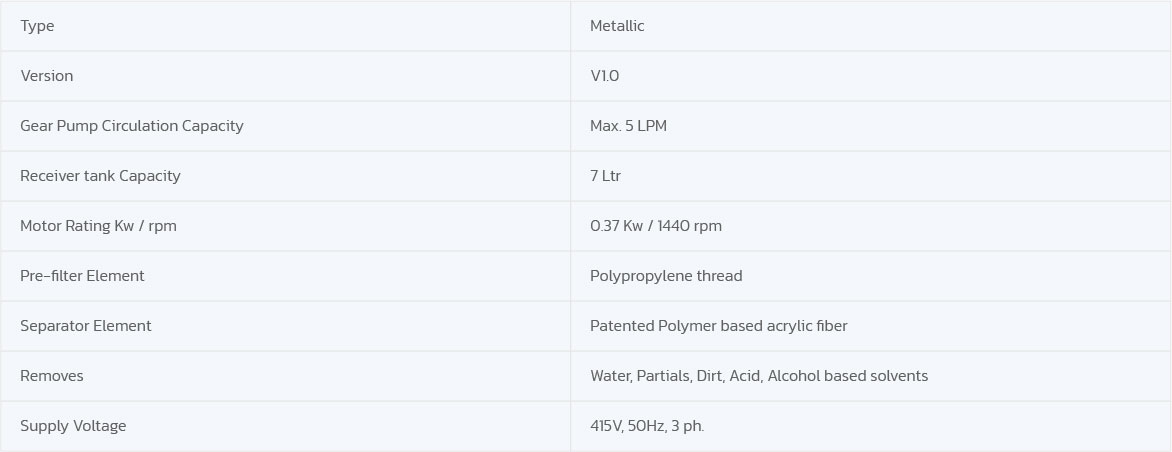

An LCCS is an accessory that can be integrated with your vacuum pump to clean and condition vacuum pump lubricants by removing water, particles, sludge, and contaminants. It improves vacuum pump performance, extends pump life, reduces oil replacement frequency, and lowers maintenance costs.

The LCCS separator element is made from patented polymer-based acrylic fiber. It forms a water film that traps moisture in the oil and separates it through density differences, ensuring cleaner and longer-lasting lubricant performance.

LCCS can be widely used in vacuum drying, vacuum deposition, vacuum brazing, vacuum packing, vacuum freeze drying, heat treatment, and vacuum impregnation applications.

The LCCS is compatible with hydrocarbon oils, vacuum pump oils, hydraulic oils, lubricant oils, and special oils such as synthetic and fluorine oils.

Contact our technical team for expert guidance. We help you select the right vacuum pump accessories based on your application, pump specifications, operating conditions, and industry requirements.

There are two types of elements used in the LCCS.

Filter Element – This element traps particles up to 10 microns. The replacement frequency depends on the number of particles present in the process and typically varies from 3 to 6 months. A pressure gauge is mounted on the LCCS; if the gauge indicates a pressure of 4 bar or higher, the element should be cleaned or replaced.

Separator Element – This is a special patented element. Since it does not absorb any liquid, its separation capacity always remains intact. There is no fixed service life for this element, and the replacement frequency generally varies from 1 year to 2 years.